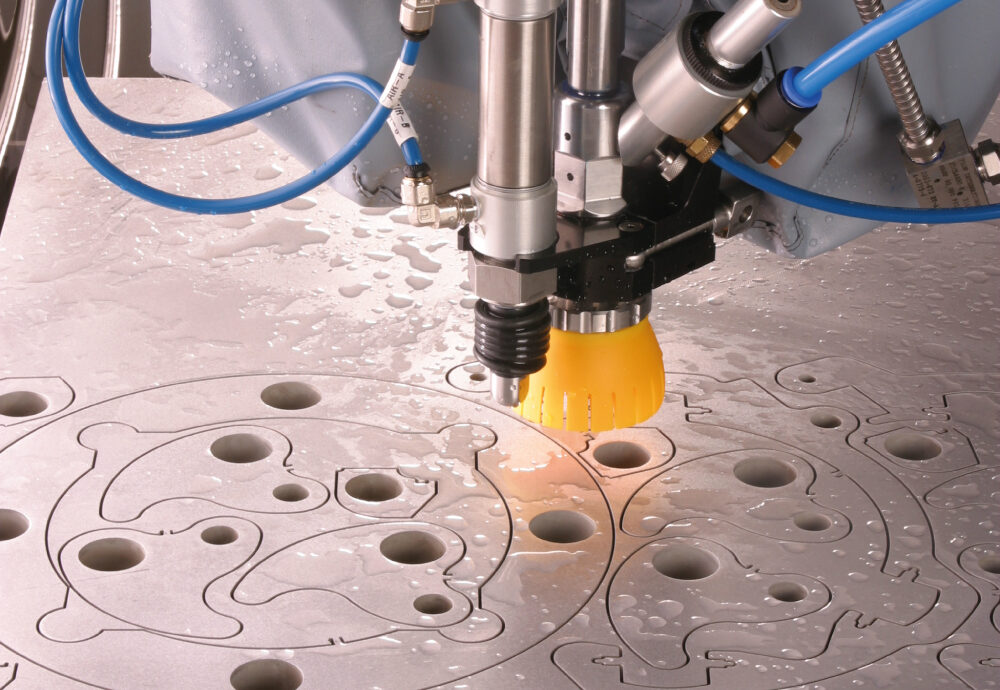

Waterjet Cutting

WECJet, also known as WEC Waterjet, offers cutting-edge waterjet cutting services for an impressive variety of materials up to 200mm thick (and 300mm thick for Aluminium). Our cutting-edge, 17,000 sq. ft. facility in Blackburn, Lancashire provides our customers with a range of cutting options and materials, including bespoke cuts with remarkable precision, courtesy of our specialist 3D & computerised motion control software. Our waterjet cutting machines offer immense cutting options and armoured plate and composite materials.

Our accreditations include the ISO9001:2015 Quality standard, and we have worked with a variety of different sectors including automotive, formula 1, construction, engineering, marine, and oil & gas.

Materials we can cut include but are not limited to: Aluminium, Copper, Brass, Bronze, Carbon Steel, Stainless Steel, Iron, Acrylics, Plastics, Carpet, Cork, Foamex, Rubber, Glass, Fibreglass, Carbon Fibre, Wood, Leather, Silicone, Granite, Limestone, Marble, Slate, Ceramics, Composites and many more.

At WECJet, we pride ourselves on our precision, with tolerances of +/- 0.005″ and better when necessary. Our advanced software and Computer Aided Design (CAD) programs enable us to produce complex shapes of all sizes, perfect for industries ranging from Aviation, Space, and Defence. With our faster cut speed (known as Q1) and selection of cutting speeds up to Q5, our customers are guaranteed high-quality results without heat, and without work-hardening the cut edges.