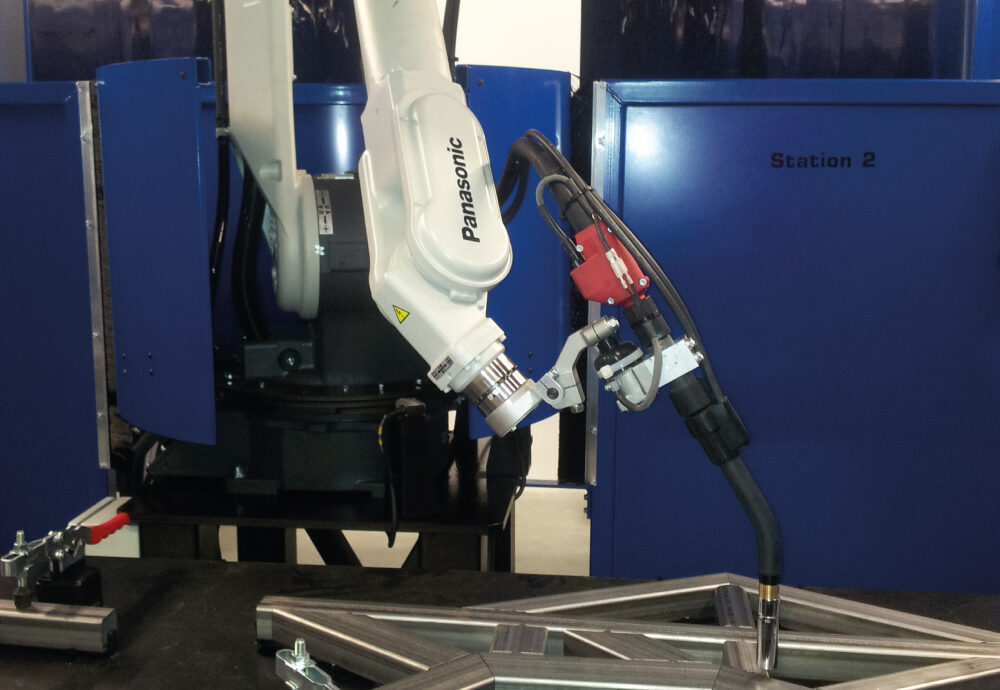

Robotic Welding

With a total of 12 robotic welding cells available in-house, the WEC Group offers a vast range of contemporary fabrication and assembly equipment that is expertly handled by over 150 skilled welders and fabricators.

In an effort to improve manufacturing speed, precision, and cost-effectiveness for our esteemed global customers, we have invested significantly in cutting-edge robotic welding technology over the past few years. This has also given us access to a large format gantry robot welding cell that can accommodate structures up to 8m long, as well as an automated hull/turret welding system featuring a 6-axis robotic arm capable of welding at a 90-degree downward angle.

Our range of equipment also includes modular Demmler jigging tables that enable us to create intricate jigs quickly and at minimal cost.

BENEFITS OF ROBOTIC WELDING:

Reliable Quality & Consistency

Robotic welding cells can perform repetitive operations for extended periods of time while maintaining a consistent level of quality. This is crucial for safety-critical components, as automation provides the assurance that weld quality will always meet the highest standards.

Reduced Waste

Automated manufacturing processes virtually eliminate waste caused by poor quality welds, which is particularly advantageous when working on high-value projects with tight turnaround times.

Improved Manufacturing Flexibility

Robotic welding cells are capable of 3-5 times faster welding speeds than manual welders, making them a valuable addition to any production line. Once programmed, they can seamlessly cycle through different processes, enabling us to meet changing product designs and customer demands with ease.