Recent WEC Projects

We undertake a range of nuclear steel fabricating projects for the biggest names in the nuclear industry.

With over 40 years manufacturing experience and with 100% right first time ethos we are able to deliver for our customers. We are a a leading force in the production of containment vessels, pressure vessels, lifting frames, hoppers & chutes.

Here are some examples of recent projects completed for our satisfied customers:

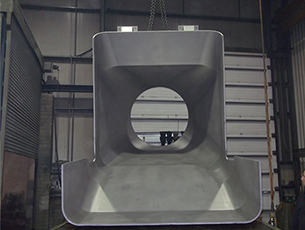

LLTP Platform Project

Designed to traverse a hazardous container from rolling stock to the processing facility and made from 100% quality Grade 2 steel, we recently completed this barrier gate for one of our valued customers.

The build to print process took 2 years with full traceability of material used. Including welding, NDT and paint reports.

Duplex Waste Handling Table

Fabricated to enable robot sorting of hazardous nuclear waste, this Duplex Waste Handling Table was fully manufactured at our WEC Group site in Darwen, using a mix of 304, 316 quality grade 2 & Duplex steel.

Working closely with the customer, the build to print fabrication process took 2.5 years to deliver a qualilty finish, with the finished product delivered to the customer ahead of schedule.

West Fence

Designed to aid the safe working at heights on a nuclear material handler, we worked with the customer to design and fabricate this protective fence.

Fabricated from quality Grade 3 steel the full build to print project took 6 months, including undergoing an extensive FAT procedure before being dispatched to site.

Other Nuclear Steel Fabricating Projects:

Carbon Steel

Carbon Steel

Stainless Steel

Carbon Steel

Carbon Steel

Carbon Steel

Stainless Steel

Stainless Steel

Carbon Steel

Stainless Steel / Duplex

Carbon Steel