Plasma Cutting

WEC Plasma – High Definition Multi Bevel Plasma Cutting.

High definition plasma cutting is an efficient profiling method utilized for stainless steel, mild/carbon steels, and aluminum components. WEC Plasma is a valuable addition to our Group’s already extensive range of subcontract engineering services, using the latest Multi Bevel High Definition Plasma Cutting technology. Located at our WECJet division’s 17,000 sq. ft. factory in Blackburn, Lancashire, WEC Plasma enhances our fabrication operations and improves our subcontract cutting capacity for thick profiles.

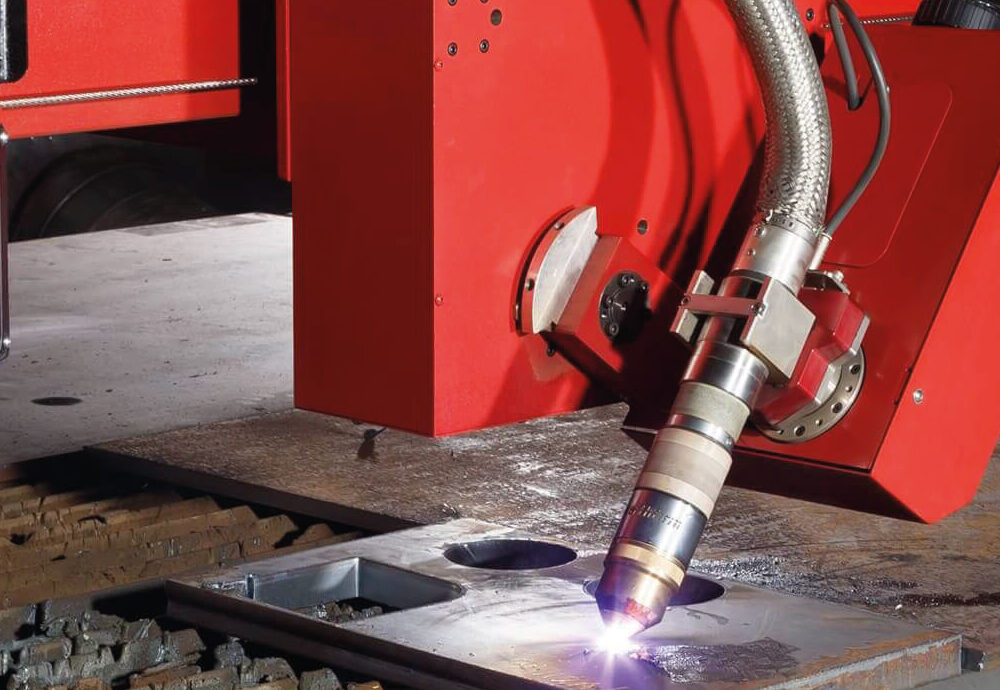

The plasma cutting process is achieved by an electrically charged gas stream (plasma), accelerated through a small hole to cut the material precisely. Our state-of-the-art plasma cutting machine has a large cutting area of 10m x 2.5m with a fully rotational bevelling head. It provides a high-speed and cost-effective plasma cutting service for components up to 50mm thick. The fully rotational head has its advantages, allowing us to cut components with a range of bevel details suitable for straight and radius edge weld preps, countersinks, and other component specifications. This includes V, A, and Top-Y style cuts with ± 50° limits.

Our Esprit Bevel plasma cutting machine fitted with “true hole” technology provides excellent holes in thicknesses above 3mm to 25mm of mild steel. Additionally, our machine has an “easy marking” capability, making plate marking for part numbers, bending lines, or marking out for assembly more accessible.

Plasma cutting offers several benefits over other methods, including rapid cutting speed, weld prep, and bevel cutting capability. It can cut through a wide range of materials and thicknesses, and the heat-affected zone (HAZ) is narrow, and the cutting method is cheaper than laser and waterjet cutting. Our in-house plasma cutting machine is CNC operated to produce clean, accurate, and sharp cuts. Recent developments in high definition plasma cutting processes have significantly improved the quality and precision, eliminating the need for edge dressing.

See our video below to observe our new high-definition plasma cutting machine in action.