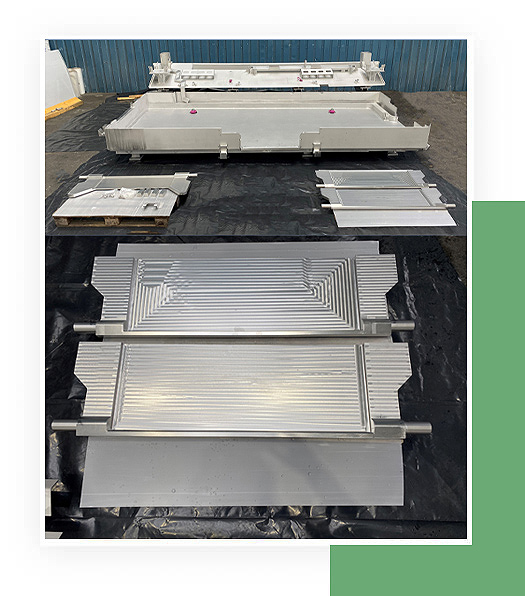

Nuclear Accredited Fabrication Company

Nuclear Manufacturing Pre-Approved Procedures for Sellafield

As a premier Nuclear Accredited Fabrication Company, we leverage extensive expertise in crafting vital Nuclear Fabrications. Our arsenal includes numerous Sellafield-approved procedures and 70 endorsed WPS. We are accredited to ISO 9001:2015, AS9100, BS EN 1090, AS 14001 and can weld to ASME standards.

To view all WEC Group certifications click here.

If you have any nuclear manufacturing requirements WEC Nuclear have a dedicated team of experts on hand to ensure the success of your project from start to finish. We offer a full in-house service from concept, through to design, fabrication & installation to ensure the finished product is exactly right.

Nuclear Accredited Fabrication Company

BEP List of Pre-Approved Procedures

- M01 – Weld Repair Procedure

- M03 – NDT – DPI Procedure

- M03 – NDT – DPI Technique Sheet – Water Soluble

- M03 – NDT – DPI Technique Sheet – Solvent Based

- M03 – NDT – MPI Procedure

- M03 – NDT – MPI Technique Sheet

- M03 – NDT – UT Procedure

- M03 – NDT – UT Technique Sheet

- M03 – NDT – Visual

- M03 – Leak Test Procedure

- M04 – Carbon Steel, Stainless Steel, Duplex & Aluminium TIG/MIG Welding Procedures

- M06 – Manufacturing / Fab Procedure

- M06 – Bending Procedure (Mild Steel)

- M06 – Bending Procedure (Stainless)

- M06 – Bending Procedure (Aluminium)

- M06 – Rectification of Distortion Procedure

- M17 – Foreign materials exclusion process procedure

- M99 – Procedure for the receipt, storage, issuance and control or welding consumables

- N03 – Storage, handling, packing and preservation procedure

- N04 – Chemical Blacking Procedure

- N04 – Elite Coatings – Coating Procedure

- N04 – SRL – Coating Procedure – System PS1 Carbon Steel & PA210

- N04 – SRL – Coating Procedure – Stainless PA210

- N06 – VECOM – Pickle & Passivation Procedure – Rev 12